In mass production, deep learning algorithms are revolutionizing areas such as quality control, fault detection, and efficiency optimization. By automating production processes through image processing and sensor data analysis, these algorithms reduce error rates and increase production speed. AI-powered systems become more effective over time due to their continuous learning capabilities.

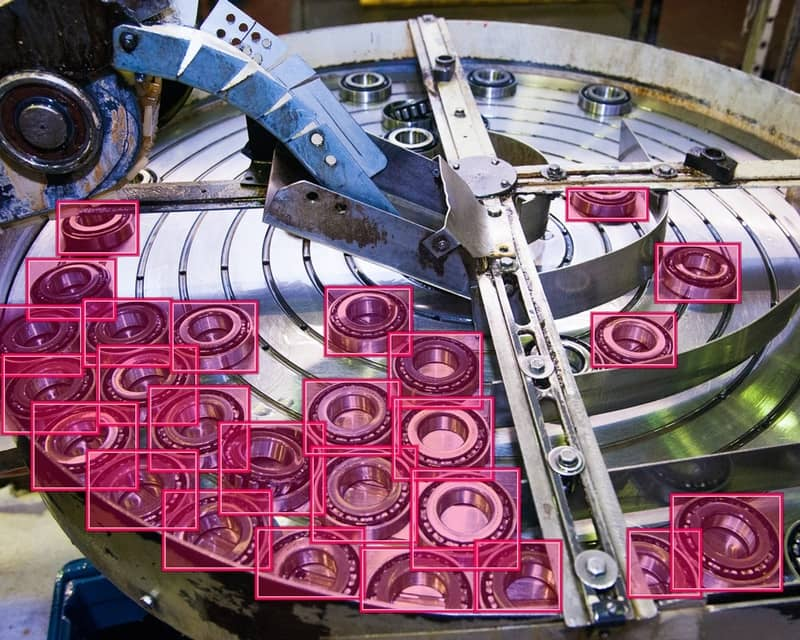

Deep learning algorithms play a significant role in manufacturing technologies, quickly addressing many issues such as detecting defective products. These algorithms can analyze vast amounts of data in real-time, identifying defects and anomalies with high accuracy. This capability leads to improved quality control, reduced waste, and increased overall efficiency in the manufacturing process.

Defect detection in manufacturing is crucial for identifying defective products and quickly resolving issues in the production process. This process provides several benefits to factories and managers:

- Time Savings: Early Defect detection allows for quick resolution of issues on the production line, ensuring uninterrupted production.

- Cost Reduction: Detecting defective products early reduces recall and repair costs, and prevents unnecessary material and energy consumption.

- Quality Improvement: Continuous and accurate damage detection enhances product quality, leading to increased customer satisfaction.

- Efficiency: Automated damage detection systems minimize human error and boost production efficiency.

These benefits increase the competitiveness of factories and improve overall business processes.

Deep Learning Algorithms for Worker Safety

Worker safety is crucial in mass production environments. Deep learning algorithms can continuously monitor whether workers are in safe zones. Data collected through cameras and sensors are analyzed in real-time, and immediate alerts are sent if workers enter hazardous areas. This prevents accidents and ensures a safe working environment.

Helmet and Glove Detection

Deep learning algorithms play a vital role in enhancing worker safety through helmet and glove detection. By utilizing advanced image processing techniques, these algorithms can analyze video feeds from cameras installed in the workplace. They accurately identify whether workers are wearing helmets and gloves, essential protective gear for many industrial environments. Real-time detection allows for immediate alerts to be sent to supervisors if any worker is found without the required safety equipment. This proactive approach not only helps in preventing accidents and injuries but also ensures compliance with safety regulations, ultimately creating a safer and more secure workplace.

Danger Zone Detection

Deep learning algorithms are crucial for detecting workers in danger zones within industrial environments. These algorithms process data from cameras and sensors installed around hazardous areas, such as machinery zones, high-temperature areas, or regions with hazardous materials. By analyzing this data in real-time, deep learning models can accurately identify if a worker has entered a restricted or dangerous area. When a worker is detected in these zones, immediate alerts are sent to supervisors and safety personnel, allowing for swift action to prevent potential accidents. This technology not only enhances worker safety by preventing unauthorized access to dangerous areas but also ensures that safety protocols are strictly followed, thereby reducing the risk of injuries and improving overall workplace safety.

Deep Learning Algorithms for Pharmaceutical Industry

Defect Detection in Pharmaceutical Packaging

In the pharmaceutical industry, ensuring the integrity of packaging is critical to maintaining product safety and efficacy. Deep learning algorithms can be used to detect damage in pharmaceutical packaging with high accuracy. By leveraging advanced image processing techniques, these algorithms analyze images and videos of packaging to identify defects such as cracks, dents, or improper seals. Real-time analysis allows for immediate identification and removal of damaged packages from the production line. This automated inspection process reduces the risk of distributing compromised products, enhances customer satisfaction by ensuring high-quality standards, and lowers the costs associated with product recalls and waste. Ultimately, deep learning algorithms help maintain the safety and reliability of pharmaceutical products throughout the supply chain.

Deep Learning for Machine Maintenance Processes

Machine Maintenance and Fault Detection

In manufacturing, regular machine maintenance and fault detection are essential to ensure continuous and efficient operations. Deep learning algorithms significantly enhance these processes by continuously monitoring machine performance through data collected from sensors and IoT devices. These algorithms analyze patterns and anomalies in the data to predict potential machine failures before they occur. By identifying early signs of wear and tear or malfunction, maintenance can be scheduled proactively, reducing unexpected downtime and preventing costly breakdowns. Additionally, deep learning models can diagnose specific issues, suggesting precise maintenance actions needed to resolve them. This predictive maintenance approach not only extends the lifespan of machinery but also optimizes maintenance schedules, leading to increased productivity and reduced operational costs.

Synthetic data in deep learning applications

Synthetic data is particularly valuable in scenarios where collecting real-world data is difficult. In specific situations, synthetic data can address numerous challenges:

- Training Data: When real-world data collection is challenging or expensive, synthetic data can be used to train deep learning algorithms. This allows for the creation of extensive and diverse datasets, improving algorithm accuracy and robustness in various scenarios.

- Simulation Testing: Synthetic data is used to simulate production processes, helping to identify and resolve potential issues and errors in advance.

- New Product Development: Synthetic data aids in testing and optimizing the performance of new product designs, speeding up the development process and reducing costs.

- Virtual Prototypes: Instead of physical prototypes, virtual prototypes can be created using synthetic data, making production processes more flexible and cost-effective.

These applications of synthetic data make manufacturing processes more efficient, flexible, and economical.

In simulation environments, conveyor belt production can be accurately replicated using synthetic data. By employing path tracing technology, highly realistic data that closely mimics real-life conditions can be generated:

- Conveyor Belt Production Simulation: Synthetic data allows for the precise simulation of conveyor belt systems used in mass production. This helps in understanding and optimizing the production flow without disrupting actual operations.

- Path Tracing Technology: Using advanced path tracing, or ray tracing, technologies, synthetic data can be generated with a high degree of realism. This technology simulates the behavior of light and materials, producing data that is very close to real-world conditions.

These capabilities enable the creation of highly accurate virtual models of manufacturing processes, improving efficiency and problem-solving in production environments.

For your synthetic data needs in manufacturing technologies, you can visit the Synth page and contact us through the communication section for more detailed information.